The Process of Aluminum Extrusion

A Great Product Comes From Simple Design

Simple design

Remelt

This process is a mixture of aluminum ingots and other raw materials are melted down to create an Alloy.

2. Billets

The result of the melting process is aluminium billet. The result is Alloy 6063 and 6061 before each billet is ready for extrusion, we test for composition with spectrometers machine to make sure each Alloy is within standard.

- 6063 is the most popular of the aluminium extrusion Alloys. This

Alloy is a good surface finish, corrosion resistant and can be heat

treated for strength.

Application : architectural, electronic parts, industrial and engineering product and general purposes. - 6061 is known for its structural strength and hardness, common

grades of 6061 is T6, indicates that the materials has been solution

heat treatened and artificially used.

Application : pole for harvesting palm oil, bike frame etc.

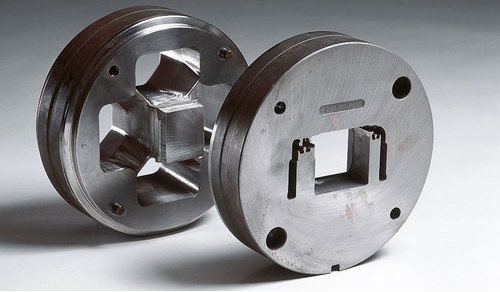

3. Dies

Design and create moulding/Dies according to our customer's specific design. We also do routine die's maintenance to make sure that end product is within standard and tolerance. Die's cost range is according to size and dimension. To start new design, contact us at : info@aluminium.co.id for Free Consultation.

4. Fabrication and Assembly

The process of making finished products made from aluminium by cutting, punching, drilling, welding and bending in a special way. Fabrication gives added value to the finished goods produced.

5. Extrusion

Extrusion is the process of shaping the materials by forcing it to flow through a shaped opening in die. The process of aluminium extrusion consist of the following steps :

- After designing and creating the shape of die, a cylindrical billet of aluminium alloy is heated to 800℉ - 925℉.

- The aluminium billet is then transferred to a loader, where a lubricant is added to prevent it from sticking to the extrusion machine, the ram or the handle.

- Substansial pressure is applied to a dummy block using a ram, which is pushes the aluminium billet into the container forcing it through the die.

- To avoid the formation of oxides, nitrogen in liquid or gassous form is introduced and allowed to flow through the section of the dies.

- The extruded part passes onto a run out table as an elongated piece that is now the same shape as aluminum die opening. It is the pulled to the cooling table where fans cool the newly created aluminum extrusion.

- When the cooling is completed, the extruded aluminum is moved to a stetcher for straightening and work hardening.

- The hardened extrusion are brought to the saw table and cut according to the required lengths.

- The final step is treat the extrusion with the heat in age ovens, which hardens the aluminum by speeding the aging process.

6. Anodizing

Each profile is coated with an oxid layer for durability, aesthetic, insulation and anti corrosion purposes. Standard colour of anodize is Clear Anodize, Black Anodize and Dark Brown Anodize.

7. Powder Coating

The profile is offered with many kind of colours. The result is a uniform, durable, high quality and attractive finish. The coating will not polutilize, oxidize or pollute the environment and suitable for indoor and outdoor purposes.

8. Quality Control

Our quality team checks for detect ensuring that every extrusion is in perfect condition and ready for packing and delivery. We follow ASTM, JIS, SII standard dimension.

9. Packing and Delivery

We offer packing with different types of materials such as plastic interleaf, cardboard and sack.

Indonesia

Indonesia English

English